As LED technology evolves, flip chip LED displays are becoming the new industry standard. Compared to traditional surface-mount device (SMD) LEDs, flip chip LEDs offer superior performance in several key areas. This shift is not random—it is driven by real technological advantages.

📌 What Is Flip Chip LED Technology?

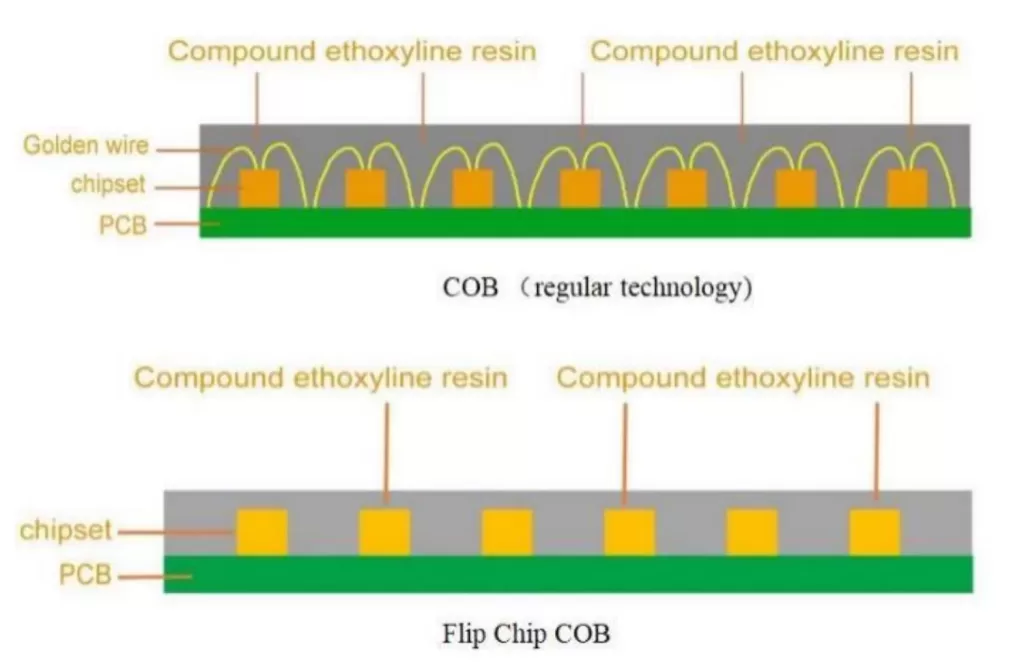

Flip chip LEDs invert the chip, so the emitting surface faces upward. Instead of using wire bonding, electrical connections are made directly through metal pads. This direct structure significantly improves efficiency and reliability.

🔄 How Does Flip Chip Differ from Traditional SMD?

Traditional SMD LEDs rely on bonding wires and a lead frame. Heat travels through the bond wires and substrate, often causing delays in dissipation. In contrast, flip chip LED displays allow heat to escape directly through the contact pads and base.

Moreover, SMD modules are more prone to wire breakage, especially in outdoor or high-vibration environments. Flip chip eliminates that risk.

🔥 Superior Heat Dissipation Means Longer Life

One key reason for the rise of flip chip LED displays is excellent thermal performance. Better heat flow prevents overheating, which often shortens the life of conventional LEDs.

As a result, flip chip modules operate more stably under high power, making them ideal for large-format or high-brightness applications.

💡 Higher Brightness with Less Power Loss

Flip chip LEDs feature lower thermal resistance. Therefore, they maintain brightness even after long hours of use. Additionally, energy loss is reduced because there are fewer intermediate materials between the chip and the heat sink.

This makes flip chip ideal for demanding environments such as outdoor billboards, stadium screens, and live events.

🔧 Higher Reliability in Harsh Conditions

Thanks to their robust structure, flip chip LED displays perform well under temperature changes, humidity, and UV exposure. Their design minimizes soldering and bonding failures, which are common in traditional SMD systems.

Consequently, flip chip displays offer better durability and lower maintenance costs over time.

📈 Greater Precision in Module Assembly

Due to smaller size and improved flatness, flip chip LEDs allow tighter pixel pitch and better surface uniformity. This enhances the image clarity, especially in fine-pitch LED displays for command centers, control rooms, and indoor exhibitions.

📦 Why Are More Manufacturers Switching?

While flip chip LEDs once cost more, ongoing advancements have made them more affordable. The benefits of heat dissipation, brightness, and reliability now outweigh the initial price difference.

Many leading LED display manufacturers are now fully adopting flip chip designs for both rental and fixed installations.

Konklusie

In summary, flip chip LED displays are gradually replacing traditional SMD solutions due to their excellent thermal performance, higher brightness, and increased durability. As demand for advanced LED displays grows, flip chip technology will continue to lead the way in performance and value.

At D-KING, we specialize in custom and rental LED displays using the latest flip chip innovations. Contact us today to explore tailored solutions that meet your display needs.